-

» Due to the small distance between the worm shaft and the housing, backflow is avoided in expansive substances.

» Direct drive via flange motor with torque arm and triple chain.

» The worm shaft receives an armor in the front area, so that no abrasion losses occur.

» The rotating motion of the worm shaft allows a continuous feed.

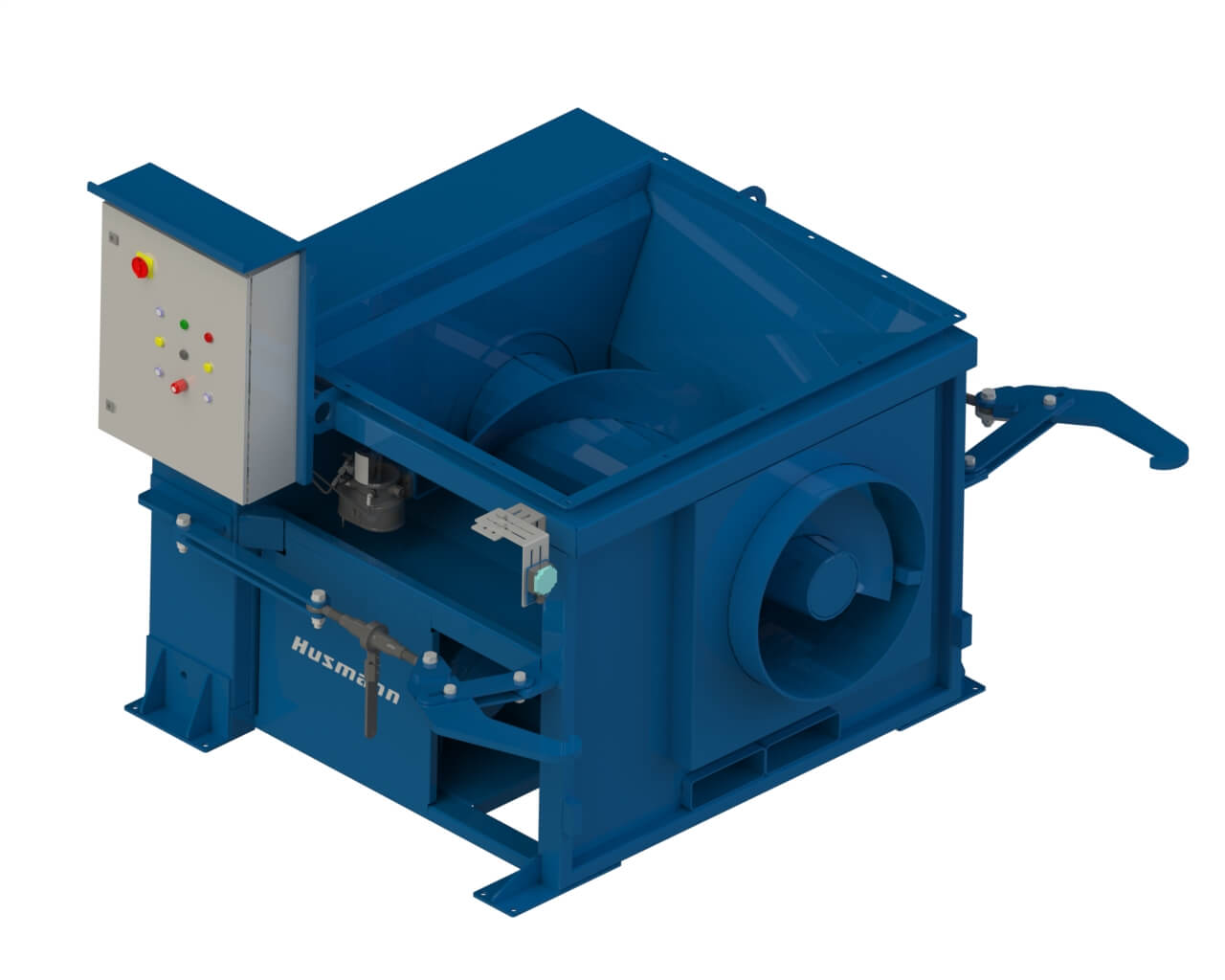

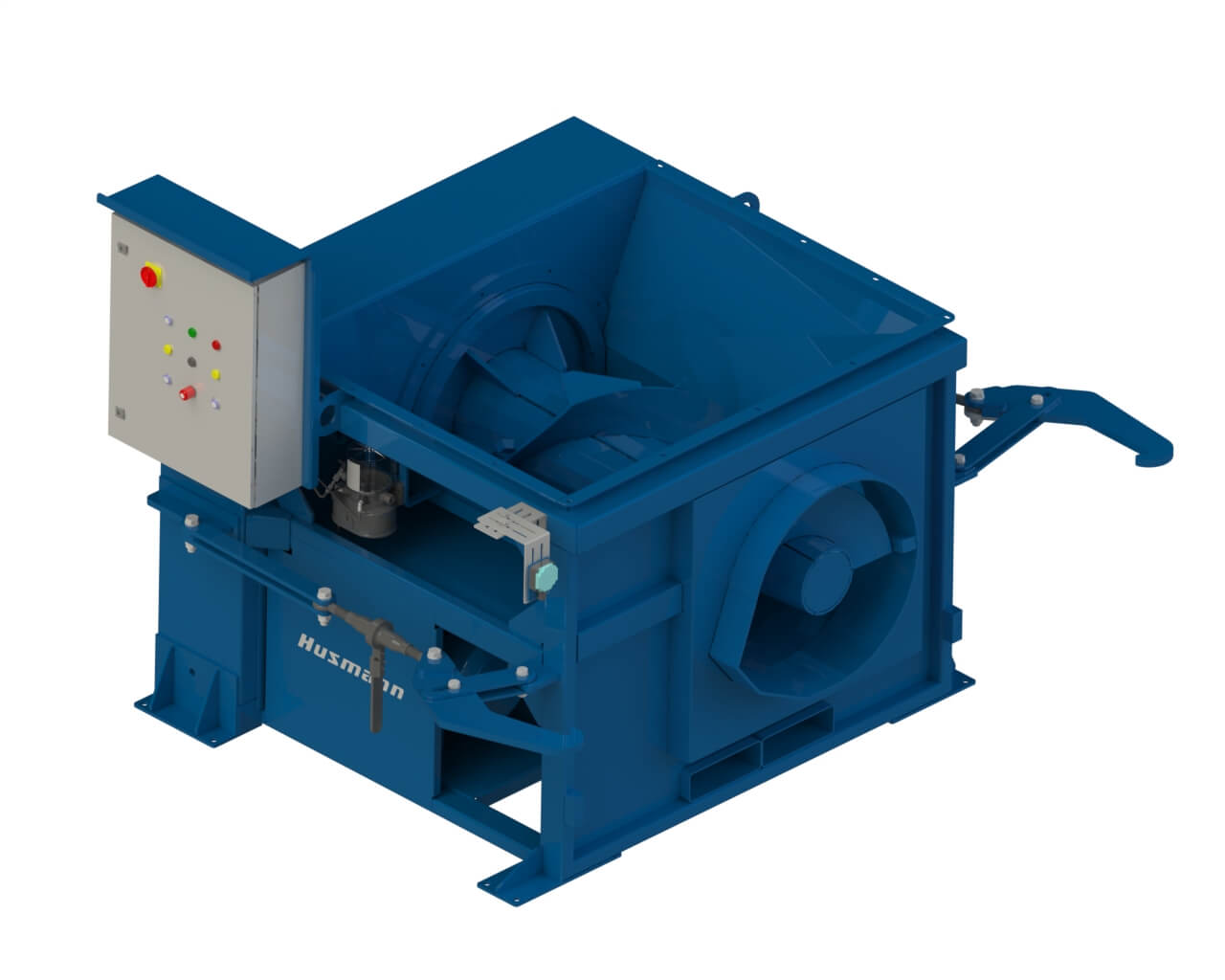

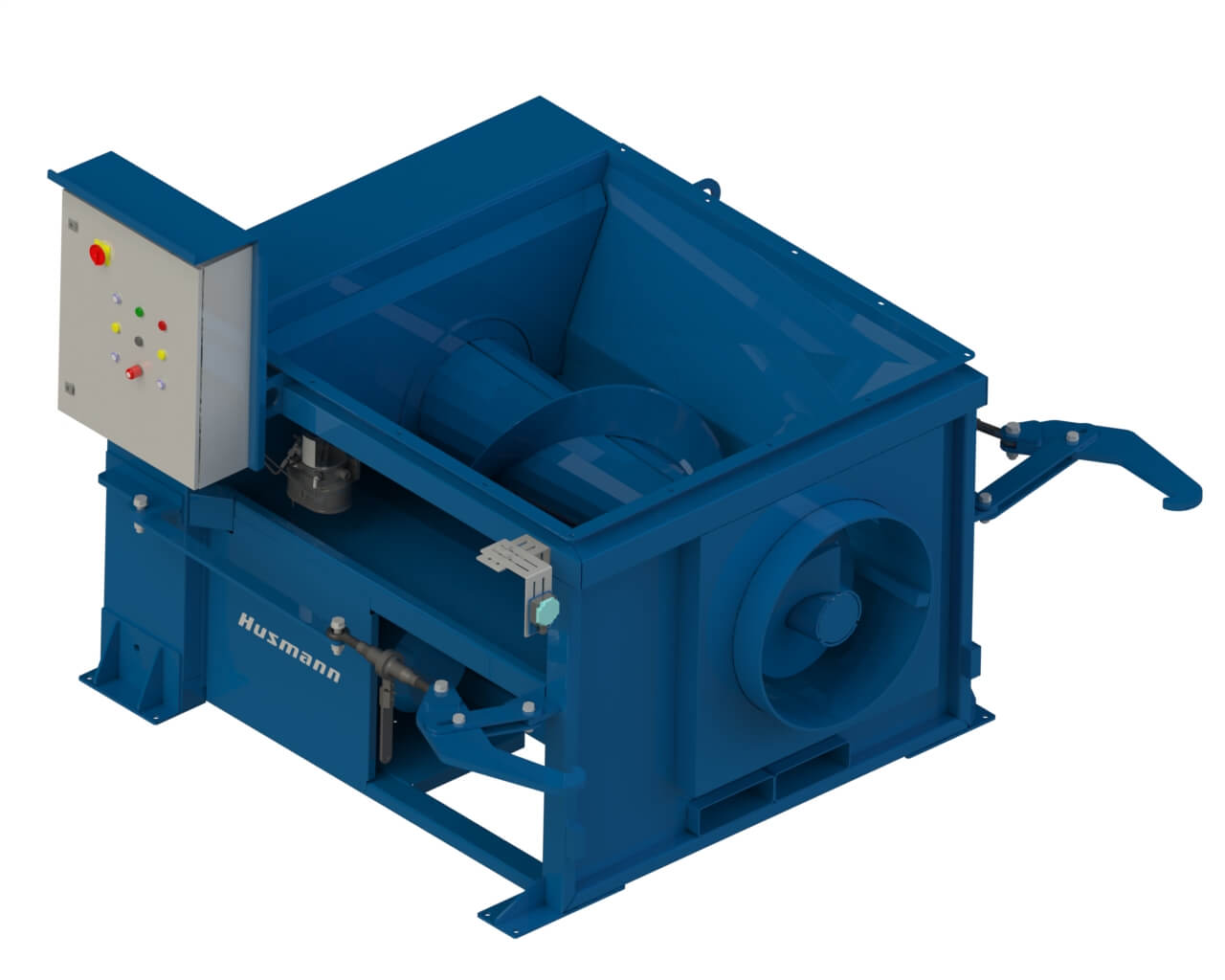

Screw Compactor HSP

The static Husmann screw compactor HSP-E is ideal for compacting cardboard boxes, foils, fruit crates or residual waste. It is characterized by its robust, low-wear construction and minimal noise development.

The machine is user-friendly, requires only a small footprint for the large filling opening and works very economically and reliably.

A slow-running, conical worm shaft detects the supplied material, crushes it and presses it into the docked container. The pre-shredding in conjunction with a high surface pressure an enormous compaction and thus a maximum filling weight of the container is achieved. If the container has the maximum filling, the container full message appears. The press switches off automatically and the press container can be changed.

Let us advise you! We are happy to offer a solution for your individual requirements!

quality features of the Husmann HSP:

-

» Due to the oversized bearing of the worm shaft a long life is achieved.

» Standard equipment with autotimer, container full controll (100%), automatic reverse device, standard hopper, “container is on” limit switch & automatic centralized lubrication system.

List of typs: Screw compactors HSP

Screw Compactor Type HSP-E-N

-

also available with increased drive power as HSP E N V

Screw Compactor Type HSP-E-N-V Wood

-

optimized for the processing of wood

-

reinforced steel construction

-

additional driver on worm shaft

Screw Compactor Type HSP-E-L-V

-

increased drive power

-

extra large filling opening

Get more information!

You would like to know more about our product?

Just send us a message and we will contact you immediately: info[at]husmann.com

Various special accessories

-

Remote control cable for fixed attachment

-

straight feeding hopper

-

upstream cardboard shredder

-

feed systems in different editions

-

tipping devices

-

level switching

-

coupling of the operation to conveyor belt, separators, etc.

Here more examples: